TATA Hitachi EH 1700-3 Dump Truck Price, Specification & Review

TATA Hitachi EH 1700-3 Dump Truck Price in India, Specifications, Review, Features

So today here in this article, I am going to introduce the TATA Hitachi EH 1700-3 Dump Truck Information such that price list, engine performance, Drive axle, Transmission, Hydraulics system, steering system, Body capacity, and more,

All kinds of information, are genuine and reliable. I hope it will helpful to you to buy or sell this model Dump Truck. Ok friends, So Let’s start it.

Also Check:

- TATA Hitachi ZAXIS 120 H

- TATA Hitachi EX 200 LC Super

- TATA Hitachi ZAXIS 220 LC

- TATA Hitachi EX 110 Super

- TATA Hitachi EH 3500AC-3

- TATA Hitachi EH 4000AC-3

- TATA Hitachi EH 1700-3 Dump Truck

- TATA Hitachi Motor Graders TG 160

- TATA Hitachi EH 5000AC-3 Dump Truck

- TATA Hitachi EH 1100-5 Dump Truck

- Tata Hitachi Dump Trucks

- TATA Hitachi EX 210 LC

- TATA Hitachi EH 1700-3 Dump Truck

TATA Hitachi EH 1100-3 Dump Truck Main Facts

- Model Code: EH 1100-3

- Engine Power: 783 KW (1050 HP)

- Max GMW: 163,300 KG

- Max Payload: 104.9 Ton

TATA Hitachi EH 1700-3 Dump Truck Price

I haven’t a genuine price so friends please contact on this Toll-Free Number and Also any other Inquiry 1800 3456 500.

TATA Hitachi EH 1700-3 Dump Truck Specification

| ENGINE | |

| Model | MTU Detroit Diesel 16V Series 2000 |

| Type | 4 Cycle, V16, diesel injection |

| Emission Certification | U.S. E.P.A Tier 2 |

| Aspiration | Turbocharged / Aftercooled |

| Rated Power | |

| SAE J1995, gross | 783 kW (1050 HP) at 2 100 min-1(rpm) |

| SAE J1349, net | 710 kW (953 HP) at 2100 min-1(rpm) |

| ISO 9249, net | 710 kW (953 HP) at 2 100 min-1(rpm) |

| EEC 80/1269, net | 710 kW (953 HP) at 2 100 min-1(rpm) |

| Maximum Torque | 4461 N·m (454.9 kgf·m) at 1 350 min-1(rpm) |

| Piston Displacement | 31.9 L |

| Bore and Stroke | 130 x 150 mm |

| Torque Rise | 25 % |

| Starting | Electric |

| OPTIONAL: | |

| Model | MTU Detroit Diesel 16V Series 2000 |

| Type | 4 Cycle, V16, diesel injection |

| Emission Certification | U.S. E.P.A Tier 2 |

| Aspiration | Turbocharged / Aftercooled |

| Rated Power | |

| SAE J1995, gross | 899 kW (1 205 HP) at 2 100 min-1(rpm) |

| SAE J1349, net | 826 kW (1 108 HP) at 2 100 min-1(rpm) |

| ISO 9249, net | 826 kW (1 108 HP) at 2 100 min-1(rpm) |

| EEC 80/1269, net | 826 kW (1 108 HP) at 2 100 min-1(rpm) |

| Maximum Torque | 5296 N·m (540 kgf·m) at 1 500 min-1(rpm) |

| Piston Displacement | 31.9 L |

| Bore and Stroke | 130 x 150 mm |

| Torque Rise | 30 % |

| Starting | Electric |

| TRANSMISSION | |

| Model | Allison H8610A |

| Design | Fully automatic, planetary type with integral lock-up converter |

| Mounting/Position | Remote from engine and rear axle for serviceability |

| Ranges | 6 forward, 2 reverse |

| Control | Allison CEC2 electronics shift system with SEM (Shift Energy Management) |

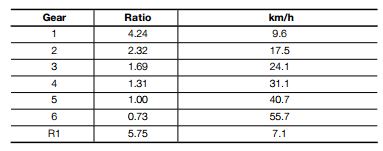

| Maximum Speeds @Rated Engine Speed with standard 27.00R49(**)E4 tires | |

|

|

| Optional: | |

| Model | Allison H9610A |

| Design | Fully automatic, planetary type with integral lock-up converter |

| Mounting/Position | Remote from engine and rear axle for serviceability |

| Ranges | 6 forward, 2 reverse |

| Control | Allison CEC2 electronics shift system with SEM (Shift Energy Management) |

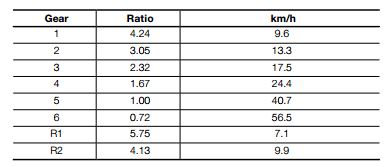

| Maximum Speeds @Rated Engine Speed with standard 27.00R49(**)E4 tires | |

|

|

| DRIVE AXLE | |

| Model Differential | 2657 |

| Axle Design | Full floating axle shafts using a model 2657 differential and single reduction planetaries at each wheel |

| Traction Control | An optional electronic feature that includes the Electronic Downhill Speed Control feature |

| Differential and Final Drive Ratios | |

| Ratios | |

| Differential | 3.15 : 1 |

| Planetary | 8.00 : 1 |

| Total Reduction | 25.2 : 1 |

| Maximum Speeds | |

| with 27.00R49 tires | 55.7 km/h |

| TIRES | |

| Front | 27.00 R49(**) E4 (Radial) |

| Rear | 27.00 R49(**) E4 (Radial) |

| Rim Width | 495 mm (19.5 in) |

| Optional tires and tread patterns may be available | |

| BODY CAPACITY | |

| m3 | |

| Struck (SAE) | 39.5 |

| Heap 3: 1 | 54.1 |

| Heap 2: 1 (SAE) | 60.4 |

| Body capacity and payload are subject to change based on customer-specific material density, options, and application. | |

| ELECTRICAL SYSTEM | |

| Twenty-four-volt starting, lighting, and accessories system. One hundred ampere alternator with integral transistorized voltage regulator. Two 12 V heavy-duty batteries capable of 1300 cold-cranking amps, each, at -18 degrees C (0 degrees F). A Hitachi solid-state reprogrammable controller controls and monitors hauler systems provide output information to control gauges and lights and incorporates connections for diagnostic tools | |

| WEIGHT | |

| Net machine weight stated below includes standard equipment | |

| Net machine weight changes will directly affect the Nominal Payload. | |

| Chassis with Hoist | 52672 kg |

| Body | 15465 kg |

| Net Machine Weight | 68137 kg |

| The Net Machine Weight specification includes operator and 100 % fuel. | |

| Nominal Payload | 95.2 tonnes |

| Target GMOW | 163 300 kg. |

| WEIGHT DISTRIBUTION | FRONT REAR |

| Empty | 48 % 52 % |

| Loaded | 33 % 67 % |

| STEERING | |

| Steering Angle | 38 degrees |

| Turning Diameter: (SAE) | 21.8 m |

| Steering Pump Output (at 2 100 min-1(rpm) | 158.1 L/min |

| System Pressure | 19.0 MPa |

| HYDRAULIC SYSTEM | |

| Body Raise Trave | 60 degrees |

| Body Raise Time (at 2100 min-1(rpm)) | 12.8 seconds |

| Body Down Time (at idle) | 15.5 seconds |

| Brake Cooling Pump Output (at 2100 min-1(rpm)) | 472 L/min |

| Hoist Pump Output (at 2100 min-1(rpm)) | 472 L/min |

| System Relief Pressure (Hoist) | 20.3 MPa |

| BRAKE SYSTEM | |

| The Brake system complies with ISO 3450 (SAE J1473). | |

| Service: | |

| All-hydraulic actuated front disc brakes and rear oil-cooled wet disc. | |

| Wet Disc Brake: | |

| The Hitachi wet disc brake is engineered for long service life even in the most extreme environments. | |

| Front Axle – Dry Disc: | |

| Disc diameter each (2 discs/axle) | 101.6 cm |

| Brake surface area per axle | 4 129 cm2 |

| Lining area per axle | 2 787 cm2 |

| Brake pressure (Max.) | 19.0 MPa |

| Rear Axle – Oil-Cooled Wet Disc: | |

| Brake surface area per axle | 79277 cm2 |

| Brake pressure (Max.) | 13.8 MPa |

| Parking: | |

| Dry disc mounted on the differential input shaft. Controlled by a toggle switch on the dash. Automatically applied in brake hydraulic pressure is lost. Size (Diameter): 686 mm | |

| Retarder: | |

| The foot-operated valve controls all-hydraulic actuation of oil-cooled wet disc brakes on the rear axle. The system provides modulated pressure to rear brakes for constant speed control. | |

| Continuous | 1051 kW (1410 HP |

| Intermittent | 1820 kW (2440 HP) |

| Load/Dump Brake Apply: | |

| Through activation of a switch by the operator, a solenoid is energized, sending full brake pressure to apply the rear Wet Disc brakes. For use during the load and dump cycles | |

| SERVICE CAPACITIES | |

| Crankcase (includes filters) | 118.3 L |

| Transmission, Cooler, and Lines | 99.0 L |

| Cooling System | 497 L |

| Fuel Tank | 1136 L |

| Hydraulics | |

| Hoist Tank and System | 448 L |

| Steering Tank and System | 170 L |

| Drive Axle (2 wheels and differential | 322 L |

| Windshield Washer Fluid | 5.7 L |

Final Words For TATA Hitachi EH 1700-3 Dump Truck

That was all about the TATA Hitachi EH 1700-3 Dump Truck, I hope you like this article, but if you have any problems regarding this article, then please comment for us. If you have any suggestions for this article, then please tell us. We will immediately apply it. Thanks for visiting our site and staying with me for more stuff like this.